Homepage /

Homepage / For the normal conditions of using floor gratings, the anti-slip properties of common forge-welded SP gratings or pressure-locked P gratings are sufficient. Anti-slip gratings must be used for environments with an occurrence of oils, ice or other impurities increasing the slip hazard and when using gratings on bridges with an inclination from 6° to 24° and it is necessary to secure high safety of the movement of people. The anti-slip design consists in a special shape finish of bearing or spacing bars. Lichtgitter offers several types of the anti-slip design of gratings for various applications.

The anti-slip types of forge-welded gratings are designated with the upper-case letter X before the designation of individual types.

Designation (for example): XSP 330-34/38-3, No. 1.

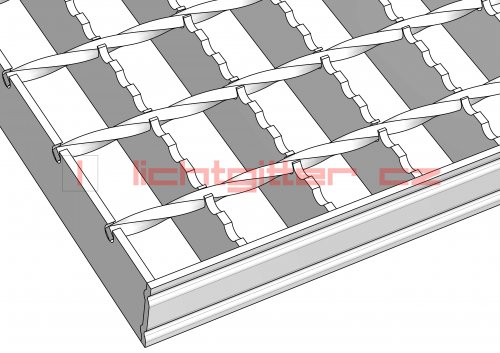

Anti-slip type No. 1

Bearing bar endlessly notched. The spacing bar is flush with the top edge of bearing bars. For the standard type of grating XSP 330-34/38-3, anti-slip class R11.

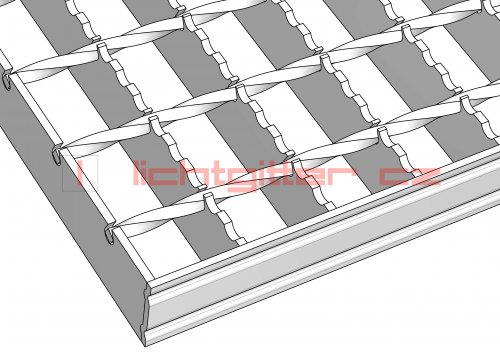

Anti-slip type No. 11

Bearing bar endlessly notched. The spacing bar is pressed approx. 2 mm below the top edge of bearing bars. For the standard type of grating XSP 330-34/38-3, anti-slip class R12.

This type can only be made on gratings with the bearing bar with thickness 2 or 3 mm, at the grating height of 25, 30 and 40 mm and with the mesh dimensions 34/38, 34/50, 34/76, and 34/101.

Forge-welded gratings, pressure-locked gratings, stair treads, perforated metal planks, spiral staircases, GRP gratings and ladder rungs. Various material variants (steel, stainless steel, aluminium) with various surface finishes.

Forge-welded gratings, pressure-locked gratings, stair treads, perforated metal planks, spiral staircases, GRP gratings and ladder rungs. Various material variants (steel, stainless steel, aluminium) with various surface finishes.  +420 596 496 511

+420 596 496 511 obchod@lichtgitter.cz

obchod@lichtgitter.cz