+420 596 496 511

+420 596 496 511 obchod@lichtgitter.cz

obchod@lichtgitter.cz

Steel S235 JR (acc. to EN 10025-2: 2004), S355J2+N; stainless steel X5CrNi18-10/ 1.4301, X6CrNiMoTi17-12-2/ 1.4571; aluminium AlMg3G22, AlMg1F15.

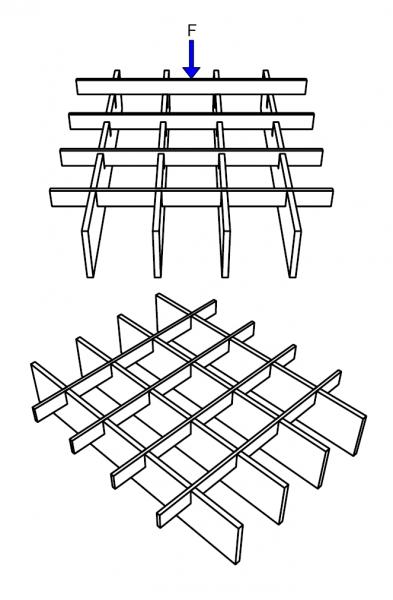

Pressure-locked gratings are made in a wide range of dimensional variants of bearing and spacing bars in such a way that the optimum type of grating can be supplied. Gratings are made to measure; the standard dimension in the direction of spacing bars (grating width) is 1400 mm, the maximum dimension in the case of machine edging (more advantageous) is 1600 mm, in the case of manual edging up to 1750 mm. The maximum length of grating (plate) is 3000 mm.

| Bearing bar height | Bearing bar thickness | |

| [mm] | 2 mm | 3 mm |

| 20 | o | o |

| 25 | o | o |

| 30 | o | o |

| 40 | o | o |

| Bearing bar pitch | Spacing bar pitch |

| 22.22 mm 33.33 mm 44.44 mm 66.66 mm |

11.11 mm 22.22 mm 33.33 mm 44.44 mm 66.66 mm 25.00 mm 50.00 mm |

For the normal conditions of using floor gratings, the anti-slip properties of standard forge-welded SP or pressure-locked P gratings are sufficient. For environments with an occurrence of oils, ice or other impurities increasing the slip hazard and when using gratings on inclined foot bridges it is necessary to use gratings with anti-slip design. The anti-slip design consists in a special shape finish of bearing or spacing bars. Lichtgitter offers several types of the anti-slip design of gratings for various applications.

The anti-slip types of pressure-locked gratings are designated with the upper-case letter X before the designation of individual types.

Designation (for example): XP 330-33-3, No. 3.

For pressure-locked XP gratings at the standard pitch of 33.33, anti-slip type No. 3 - on both the bearing and spacing bars - is supplied.

Forge-welded gratings, pressure-locked gratings, stair treads, perforated metal planks, spiral staircases, GRP gratings and ladder rungs. Various material variants (steel, stainless steel, aluminium) with various surface finishes.

Forge-welded gratings, pressure-locked gratings, stair treads, perforated metal planks, spiral staircases, GRP gratings and ladder rungs. Various material variants (steel, stainless steel, aluminium) with various surface finishes.  +420 596 496 511

+420 596 496 511 obchod@lichtgitter.cz

obchod@lichtgitter.cz